TMV-1

| Long. Travel | 39 in. |

|---|---|

| Cross Travel | 16.3 in. |

| Taper, HP | NT-40, 5 hp |

| Slide Ways | Box Ways |

| Spindle | Variable Speed |

| Long. Travel | 39 in. |

|---|---|

| Cross Travel | 16.3 in. |

| Taper, HP | NT-40, 5 hp |

| Slide Ways | Box Ways |

| Spindle | Variable Speed |

This model Vertical Knee Mill is constructed with box ways instead of dove tail ways. The model has many unique features compared with most of the similar machines on the market.

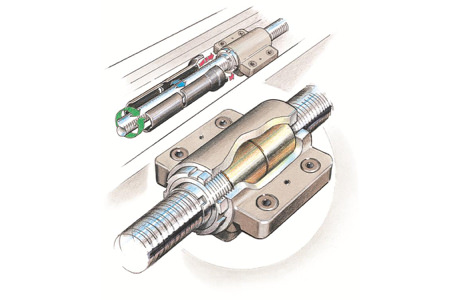

The quill is CNC ground to a mirror finish and chromed to fit the housing resulting in close to jig bore accuracy for quill downfeed.

Tapered gibs installed on the ways allows easy adjustment for long term usage.

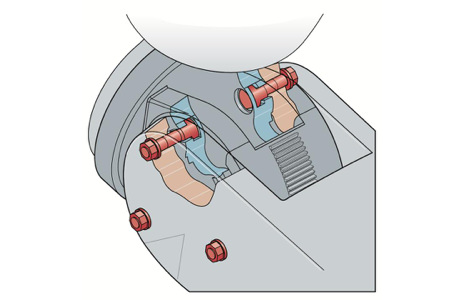

The feed handles are designed to spin free which eliminates the friction between the operator’s hand and the feed handle.

The bottom of the saddle, instead of the top of the knee ways, which rides on the knee, is hand scraped for better oil retention and prevent dirt and chips from embedded in the knee ways.

Hardened and Ground box ways on the vertical column and base offer extra support under heavy cutting conditions.

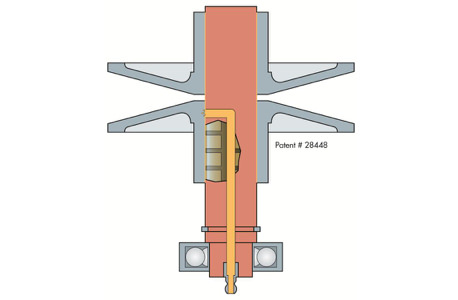

Easy Access Lubricating Shaft is designed with an oil channel in the center that is fed by a grease fitting at the lower end for longer motor shaft life. (Patent No. 2848)

| Capacity | Inch | Metric |

|---|---|---|

| Table Size | 10 x 54 in. | 254 x 1371 mm |

| T-slots (No., Size, Pitch ) | 3, 5/8, 2.5 in. | 3, 16, 63.5 mm |

| Table Travel : X Longitudinal | 39 in. | 990 mm |

| Table travel : Y Cross | 16.3 in. | 414 mm |

| Quill travel: Z Vertical | 5 in. | 127 mm |

| Ram Travel | 18.5 in. | 470 mm |

| Knee travel : Vertical | 15.3 in. | 388 mm |

| Spindle Center to Column | 9.8 - 28.3 in. | 248 - 718 mm |

| Spindle Nose to Table Top | 5.375-16.9 in. | 136.5-429 mm |

| Head, Spindle | Inch | Metric |

|---|---|---|

| Spindle Nose Taper | NT-40 | |

| Spindle Variable Speed Range | 60-4500 rpm | |

| Spindle Motor (220V/440V) | 5 HP | |

Quill Feed (Inch/Rev)(3 speeds) | .0015, .003, .006 in. | .038, .076, .152 mm |

| Quill Diameter | 4.2 in. | 106.68 mm |

| Head Swivel Angle | 360° | |

| Head Tilt Angle (L/R) | 90° | |

| Head Tilt Angle (Up/Down) | 45° |

| General | Inch | Metric |

|---|---|---|

| Floor Area (W x D x H) | 9.83 x 6.25 x 7.64 ft. | 2.99 x 1.9 x 2.32 M |

| Approximate Weight | 3,300 lbs. | 1,496.85 Kg |

| Power Consumption (220V) | 3 KVA/8 amps | |

| Power Consumption (440V) | 3 KVA/4 amps |

All specifications subject to change without notice. Please call to verify.

| Long. Travel | 30 in. |

|---|---|

| Cross Travel | 12 in. |

| Taper, HP | R-8, 3 hp |

| Slide Ways | Dove Tail |

| Spindle | Variable Speed |

| Long. Travel | 37 in. |

|---|---|

| Cross Travel | 12 in. |

| Taper, HP | R-8, 3 hp |

| Slide Ways | Dove Tail |

| Spindle | Digital Variable Speed |

| Long. Travel | 37 in. |

|---|---|

| Cross Travel | 12 in. |

| Taper, HP | R-8, 3 hp |

| Slide Ways | Dove Tail |

| Spindle | Variable Speed |

| Long. Travel | 39 in. |

|---|---|

| Cross Travel | 16.3 in. |

| Taper, HP | R-8, 3 hp |

| Slide Ways | Box Ways |

| Spindle | Variable Speed |

| Long. Travel | 39 in. |

|---|---|

| Cross Travel | 16.3 in. |

| Taper, HP | R-8, 3 hp |

| Slide Ways | Box Ways |

| Spindle | Digital Variable Speed |

| Long. Travel | 40 in. |

|---|---|

| Cross Travel | 16 in. |

| Taper, HP | NT-40, 5 hp |

| Slide Ways | Box Ways |

| Spindle | Digital Variable Speed |

Don’t overpay for a competitor’s machine until you see how a high-quality Sharp machine stacks up. Request a quote to see the Sharp difference for yourself.

Contact us to purchase your next machine or to find your local authorized Sharp Precision Machine Tool dealer for genuine parts and service.

Register to keep up to date with our monthly newsletter containing the latest information and specials.